An individual axis locking, toolbar clamp, for weeding machinery and other uses.

After decades of being frustrated with the design of the toolbar clamps on weeding machinery, and nearly a decade of sitting on the idea, and weeks of working out the best solution, I have finalised my design for a user friendly, light but strong and simple to build toolbar clamp, which I have very immodestly called the ‘Merf clamp’.

Download the design from the Physical Weed Control Forum Website

Mechanical weeding is becoming ever more important due to challenges to herbicides, such as evolved resistance and legislative prohibitions. One of the main alternatives to herbicides are mechanical weeders, such as interrow hoes. Many mechanical weeders have weeding tools, such as hoe blades, attached to a toolbar by a clamp. There have been many clamp designs made over many years, but from the perspective of the end user they all suffer from a number of deficiencies.

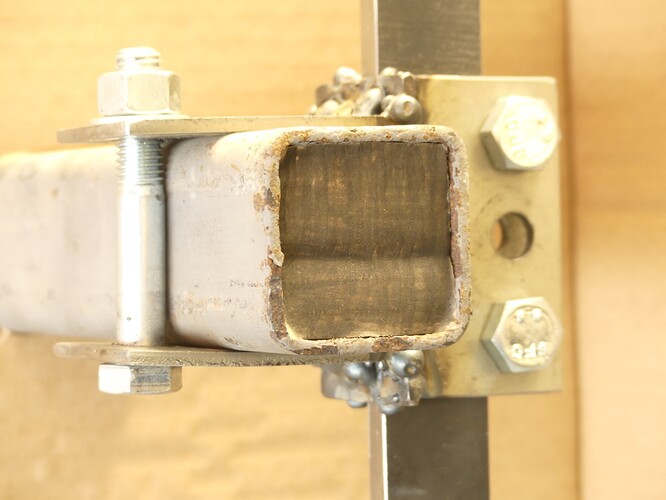

The main problem on many clamps is that a single bolt locks both the horizontal adjustment of the clamp along the toolbar, and the vertical adjustment of the tool leg. While simple in design and engineering, it means that when only one axis needs adjusting both axes are loosened and the axis that does not need adjustment can move and lose its position, making them difficult to position accurately. While more complex, it is better for each axis to have its own individual locking system.

A few clamps need to be slid onto the end of the toolbar, which is problematic if there are already other tools mounted on the bar that are in the way. Ideally a clamp should be able to be directly slid onto the toolbar in the exact location it is required. Similarly many clamps require the tool leg to be slid up through the clamp. This may require the machinery to be lifted up to allow the tool leg to be slid into the clamp, or other inconveniences.

A lot of clamps use a locking system where the end of a bolt or set screw pushes against part of the tool leg and / or toolbar. This can result in the end of the bolt or set screw becoming damaged, such that it cannot be taken out of the clamp. Likewise the area on the toolbar and tool leg where the bolt impinges can be damaged, making it difficult to move along the toolbar and move the tool leg inside the clamp.

To address these limitations a new design of toolbar clamp has been invented. The overall design aims of the clamp are:

- Each axis has its own individual locking system;

- The clamp can be placed directly on the toolbar, not slid on from the ends;

- Likewise, the tool leg can placed into the clamp, rather than having to be slid in from the end;

- Locking the tool leg and toolbar in the clamp is done by squeezing the clamp rather than driving the end of the bolt into the tool leg or toolbar, thus avoiding damage to toolbar, tool leg and bolts;

- That the clamp can be easily removed from the toolbar with the tool leg held in position, so the tool can be quickly and easily moved to another location on the toolbar without needing to readjust the tool leg;

- Be as lightweight as possible, achieving strength through design, rather than thickness of steel;

- Be simple to construct:

- The basic version only needs a saw, a drill and a welder to construct from flat mild steel bar;

- Where profile cutting is available, the more complex shaped parts lock together like a jigsaw to ensure accurate dimensions, easy construction and extra strength;

- No bending is required, as this typically requires specialist machinery.

- Be easy to use - only one spanner is required, bolt heads are prevented from rotating by a ‘locking bar’ which still allows a crescent spanner to be used on the head if extra leverage is needed (e.g. a seized nut);

- Have no loose parts that can be lost;

- Does not have any bolt threads in the body of the clamp that can get damaged, rust up etc.;

- Bolts and nuts for clamping are easily removed (even cut off) and replaced if damaged;

- Overall the clamp complies with the KISS principle en.wikipedia.org/wiki/KISS_principle.

The result is the 'Merf clamp'! The design has been made freely avalible under an Open Hardware Licence and is avalible for free from the Physical Weed Control Forum Website